EY Entrepreneur of the Year Award winner Sam Moffett, CEO and founder of Moffett Automated Storage, talks to ThinkBusiness about scaling a global engineering business from Monaghan and driving the digital, automated supply chain.

When he was in school, while some kids were playing football or passing time on games consoles Sam Moffett was driving forklifts and other forms of heavy machinery. For him, the family business was engineering and manufacturing and machines were his playground and a university.

Sam is the son of renowned engineer Robert Moffett, who founded the international Irish-headquartered forklift brand Combilift.

“My ambition for the business is to keep it on an organic growth path and drive towards having a turnover of €500m by 2030”

Robert won renown initially in the 1970s for the Moffett Mounty truck mounted forklift of which there are thousands operational all over the world and Combilift today is growing rapidly worldwide.

You could say engineering is in Sam’s blood as his grandfather Cecil was also a renowned engineer who pioneered innovation in agricultural machinery in Ireland from the 1940s until his untimely death in 1972.

In recent months Sam Moffett, the founder and managing director of Moffett Automated Storage (MAS) was named the emerging and overall EY Entrepreneur of the Year for 2023.

The same day Moffett won the EY Entrepreneur of the Year Award he was also awarded Monaghan Business Person of the Year for 2023.

Battling from Clontibret

“I didn’t have the toys, I was driving the real thing. I had an interest in machines since I was five years old. I used every opportunity to get an insight into the business and I worked every weekend and summer holiday I could. I really enjoy engineering”

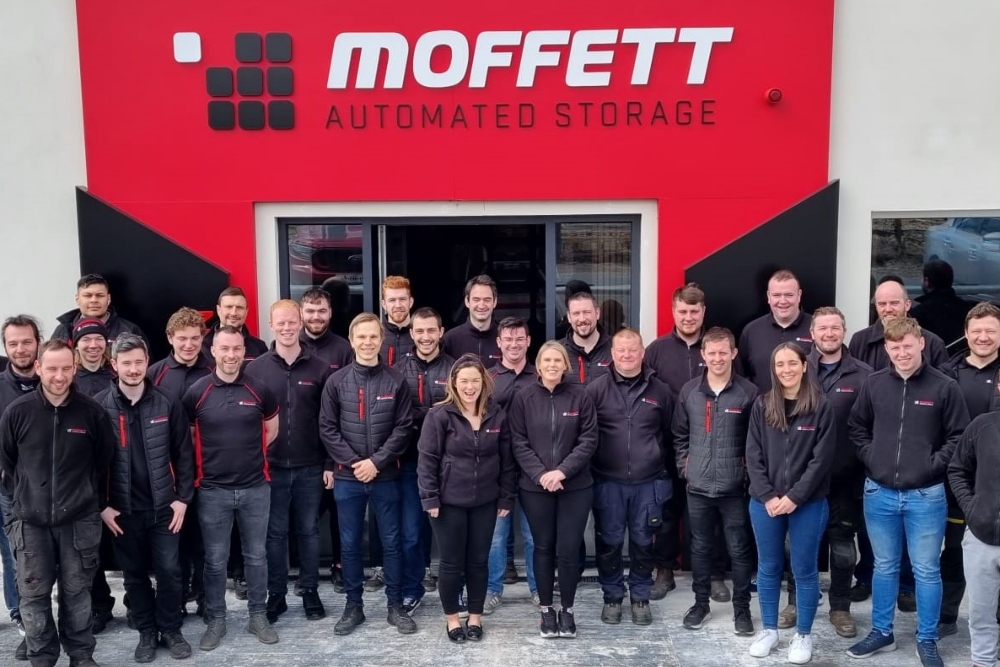

Headquartered in Clontibret, Monaghan, and employing 65 people, Moffett Automated Storage Ltd specialises in the development of innovative, automated pallet storage and warehousing solutions. Think of it as robots on lifts and tracks who whir up and through warehouses to bring heavy pallets of goods to and from awaiting trucks.

The company, which began operating in 2017, designs, manufactures, installs, and supports fully integrated automated warehouse pallet storage systems that enables end users to pick and pack from palletised materials. This disruptive, dynamic business offers a range of cost, operational and sustainability benefits to clients. It enables clients to double the storage capacity within existing warehouse facilities and can reduce the energy usage of companies operating within a freezer environment in the cold storage industry by 50%.

Moffett’s pallet storage and retrieval system is controlled by proprietary software also developed in-house by the Moffett team.

Last year, thanks to a growing client list in more than 10 countries seeking its automated warehouse, MAS revealed plans to add 30 new jobs at its head office.

All MAS solutions are linked to its proprietary warehouse management software allowing organisation of pallets to be automated. Items for dispatch are waiting by the door exactly when they’re needed, meaning a substantial efficiency upgrade for clients.

Scaling new heights

Pictured at the EY Entrepreneur Of The Year awards were: Roger Wallace, Partner Lead EY Entrepreneur Of The Year Ireland; Dr Andrew Woods, CEO and Founder CATAGEN; Tom Walsh, CEO and Founder, Staycity; Eimear McCrann, Director, EY Entrepreneur Of The Year Ireland; Sam Moffett, Managing Director and Founder Moffett Automated Storage; Anne Heraty, Chair of the EY Entrepreneur Of The Year judging panel; Ciaran Marron, CEO and Founder, Activ8 Solar Energies; and Frank O’Keeffe, Managing Partner EY Ireland. Photo: Naoise Culhane

Recalling growing up in an entrepreneurial household surrounded by heavy machinery he says: “I didn’t have the toys, I was driving the real thing. I had an interest in machines since I was five years old. I used every opportunity to get an insight into the business and I worked every weekend and summer holiday I could. I really enjoy engineering.”

Moffett went straight from school into the family business having spent the previous five years using every school break and summer holiday to work in the firm. He was no stranger to assembly lines and R&D and got stuck in.

The opportunity to project manage the construction of a new 11-acre manufacturing facility for Combilift provided Moffett with the ‘Eureka’ moment he needed.

“The project took about three years and as we neared the end and I was putting in various factory automation systems I realised something new was needed when you consider digital technology allied with automated systems.

“Automation is not competition to the family business, it’s a completely new sector. I spoke to my father and we agreed that my idea of an automated warehouse wouldn’t fit within the umbrella of the existing business and the dealers we work with and so he encouraged me to try this on my own. He agreed that automation is the future and said ‘knock yourself out.’”

Moffett established MAS on the same site that his father originally founded the Moffett Mounty in a shed he built himself and where Combilift was also started.

As he continued to project manage the Combilift factory expansion and worked on MAS at nights, Sam Moffett met with Enterprise Ireland and was granted a Market Discovery Fund grant that enabled him to hire a design engineer and a software engineer.

They worked hard on the idea of an automated warehouse for 15 months developing the hardware and the software to develop a smart automated warehouse. One of the biggest challenges was convincing potential clients in the cold storage and logistics industries to take the leap and deploy the MAS system.

“We manufacture everything in-house. The software would be 50% of the business. We manufacture everything and we install everything. And from Monaghan we can remotely support every piece of equipment for our customers, 24 hours a day worldwide.”

The turning point for MAS was the Covid-19 pandemic and very soon food and logistics businesses around the world were keen to deploy the automated system.

MAS typically has over 8-to-12 live projects in four different countries around the world, each ranging from storage of 5,000 pallets to 15,000 pallets. The system has no limitations on height of the warehouse allowing company use their footprint to the maximum.

It now has clients spread from Europe to the Middle East and Asia. Moffett said that the challenge is keeping up with demand but also innovation is driving the business into new areas of automation that he is reluctant to talk about just yet. “If we want to stay competitive in the market we have to look at a few niches. Our product has to be niche otherwise we’d have a lot more competition.”

MAS currently has revenues of around €17.5m. “We’ve been working very hard and we are looking to hit the €30m mark in the next year, so we are vectoring up for sure.”

Automation is the future

Because each MAS installation is unique, requiring bespoke manufacturing and structural engineering, timelines can be tight and running into roadblocks such as unfinished construction are par for the course. “The challenges can be amazing and as a result I am not an expert in any one thing but have cultivated quite a bit of knowledge over many things.

“There is no reason why you can’t turn a forklift operator into an automation mechanic. Automation is effectively evolution. We’ve been automating things since the Stone Age”

“Crucially, it is about giving customers a return on their investment. The key to it is density. To get the density right, the only way is up. So we typically do installations that are 25 or 30 metres high. Unlike warehouses that would require a handful of forklifts, this would be a different industry that would require 10X the investment.”

In many ways, Moffett is pushing the envelope on the future of automated storage for a world where an efficient supply chain is king, digital is the oxygen and efficiency is the currency.

“My ambition for MAS is to keep it on an organic growth path and drive towards having a turnover of €500m by 2030. We see where the potential is for the industry that we are in. As long as we can keep ahead of the game and keep growing the opportunities with automation are endless.”

Moffett challenges the narrative that automation will steal jobs. If anything he believes automation will create more jobs. “We see opportunities for people to take on better roles through upskilling. There is no reason why you can’t turn a forklift operator into an automation mechanic. Automation is effectively evolution. We’ve been automating things since the Stone Age.”

He makes an eloquent point. Technology shifts actually result in job creation, rather than the opposite. The tools and technologies change, therefore people need to change too. In many ways innovation frees people to focus on higher value, higher productivity roles. “From tractors on farms helping farmers to do more to traffic lights doing the work policemen used to do and automated passport control in airports , it’s all an evolution.”

Moffett believes that innovation can come from anywhere and his family have proven it with the Moffett Mounty, Combilift and more recently with MAS. “There was research from Grant Thornton that named Monaghan the most entrepreneurial county in Ireland. That was pretty inspiring to hear but also a challenge when you’re trying to recruit people in to your business. But it’s a good place to do business and grow a business.”

To prove his point about Monaghan, one of Moffett’s fellow finalists in the EY Entrepreneur of the Year Awards was Ciaran Marron from Activ8 Energies who was named 2023 EY Established Entrepreneur Of The Year for 2023, whose business is located in Carrickmacross.

“It’s a small county but has demonstrated it has the potential to grow big companies. As well as Combilift and Activ8, we have Monaghan Mushrooms and Silver Hill, to name a few.

“My ambition for Moffett Automated Storage is that we stay local and grow. I’d like to see the local area develop into bigger towns because we have the land. I think what Monaghan is missing at the moment is the social aspect. It needs a bit of a lift if we are going to encourage younger people to stay or to return here to grow their careers and offer an alternative to long commutes.”

Winning the overall Entrepreneur of the Year Award is one thing, but for Moffett it is about the camaraderie he has experienced.

“I’ve heard so many inspirational stories from a lot of businesses that I felt were much more superior. I was just delighted to be among them and to know I can reach out to them to discuss business challenges and opportunities. Because I’m in rural Ireland, it’s not like I can just walk down the street. So being part of the alumni is great.

“To operate a business is still pretty much the same thing, regardless of what industry you are in. We are all dealing with the same types of growth problems, the pains, hiring people, paying rates, but at the end of the day business is business.”